Innovative Waterjet Technology Maintenance for Light & Heavy Rail Optimal Performance & Longevity Sustainable, Flexible Solutions Reliable Schedules & Increased Capacity

Extend Rail Lifetime with Cost Effective

Innovative Waterjet Technology

In modular and scalable applications for Rail Wagons & Truck based Rail Vehicles

At Rail Restore, we recognize that safety is essential in rail maintenance, alongside the importance of efficiency and effectiveness.

That is why we have developed a cutting-edge solution that combines your valuable input with our state-of-the-art Waterjet Technology to extend the life of your rails.

Comprehensive rail maintenance for light and heavy rail

Our Waterjet Technology is designed to provide top-notch maintenance services for both light and heavy rail systems. With Rail Restore, you can ensure optimal performance and longevity of your rail infrastructure, regardless of its size or complexity.

Sustainable, flexible solutions for reliable schedules and increased railway network capacity

Rail Restore sustainable rail maintenance solutions offer unparalleled flexibility to accommodate your unique needs. By implementing our eco-friendly Waterjet Technology, you can maintain reliable schedules and even increase the capacity of your railway network. Together, we’ll pave the way for a more efficient and sustainable future in rail transportation.

Quality you can trust, validated by independent, comprehensive testing and analysis by Dekra Rail. Proven to increase traction and improve detection.

THE RAIL RESTORE Approach

PRECISION CLEANING

Improving safety and punctuality of your network

- Applications:

- Removal of insulating layer(leaves/rust).

- Cleaning slippery surface (leaves/grease).

- Removal of an isolating and slippery layer (no material removal).

- Removal of rust.

- Groove cleaning.

- For groove and Vignole rail.

- Proven quality based on independent external analysis.

- In modular and scalable applications from rail-road vehicles

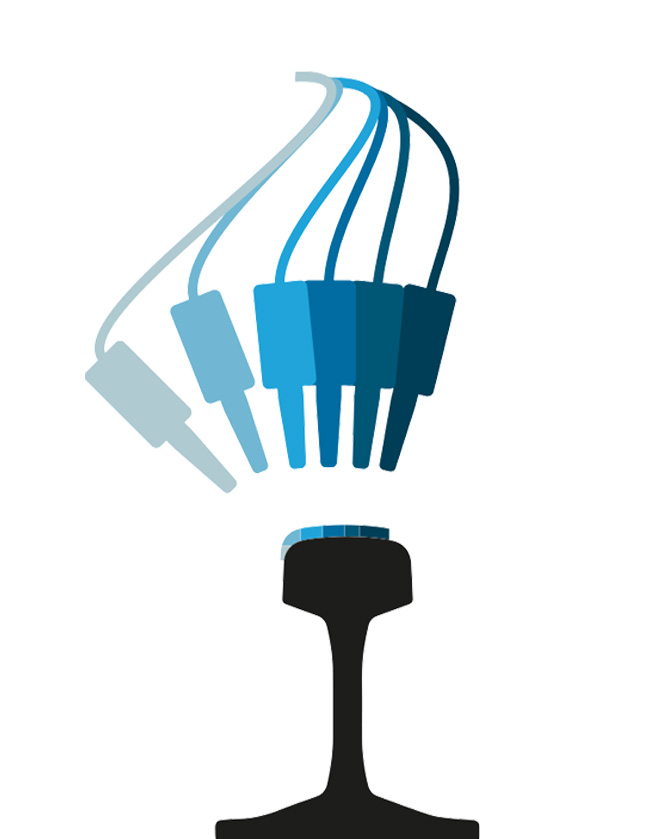

to train-based solutions. - Single nozzle (per rail) up to 2.500 bar waterpower.

THE RAIL RESTORE Approach

MATERIAL REMOVAL

Improving lifetime of your assets

- Applications:

- Preventive maintenance (cyclic program.

- Minor profile changes (anti head check profile).

- Removal of small damages (like ballast imprints).

- Removal of mill Cale and decarbonized layer.

- Removal of ~0.2 mm material (steel).

- For groove and vignole rail.

- Unique nozzle setup up to 4.000 bar waterpower.

THE RAIL RESTORE Approach

Pioneering the future of rail maintenance through

Innovation and Collaboration

We are dedicated to revolutionizing the rail maintenance industry by focusing on research, development and innovation.

With worldwide patents and over a decade of technology development experience we are committed to provide you with the smartest and most efficient rail maintenance solutions.

Rail Restore: a proud member of the Plasser Group!

Plasser & Theurer, a family-owned Austrian company, is renowned for its comprehensive range of advanced machinery designed to support all aspects of railway infrastructure. From inspection and maintenance to construction and modernization, their equipment ensures the highest standards of efficiency and precision in rail track management.

More information about Plasser & Theurer can be found here.

TECHNOLOGY ADVANTAGES

The Rail Restore Difference

Rail Restore’s Waterjet Technology is transforming the rail maintenance landscape by offering significant advantages over traditional methods.

Our cutting-edge approach delivers superior proven results, ensuring the safety, efficiency and sustainability of your rail system.

key benefits of using Rail Restore's Waterjet Technology

for rail maintenance

in comparison to conventional methods:

Environmental Advantages

- Clean & Green:

With no fine particles and low CO2 emissions, our process minimizes environmental impact. - Zero Sparks, Zero Fire Risk:

Our waterjet technology eliminates fire hazards, ensuring safety for both your infrastructure an crews. - Organic Materials Only:

We use only water and sand, reducing your carbon footprint while maintaining high-quality service.

Operational Efficiency

- Quick and Convenient:

Our efficient process significantly reduces time for maintenance, resulting in minimal service disruptions. It is possible to implement the solution in daytime operations. - Competitive Operating Costs:

Utilizing long-life wear parts, water and abrasive (sand), our solution is cost efficient. - Flexible Applications:

Adaptable to a wide range of rail types, conditions and even high-risk locations like bridges and tunnels (no fire hazards).

Material Integrity

- No Heat, No Problems:

Our process ensures zero heat-related damages. - Preserved Microstructure:

The steel of your rail always stays in optimal condition. - Extended Lifespan:

Your rail will deliver peak performance for years to come.

Material Integrity

- No Heat, No Problems:

Our process ensures zero heat-related damages. - Preserved Microstructure:

The steel of your rail always stays in optimal condition. - Extended Lifespan:

Your rail will deliver peak performance for years to come.

Customized Setups:

- Pressure Ranges:

Our high-pressure waterjet operates between 2.000 to 4.000 bar, accommodating all varieties of maintenance. - Abrasive Addition:

Controlled addition of natural abrasive materials ensures effective treatment. - Customized Solutions:

Unique cutting heads ‘nozzles’ and ‘nozzle-setup’. designed for every application for Rail Wagons and Truck based Rail Vehicles..

By using our high-pressure waterjet for Rail Treatment, you are choosing for a safe, sustainable, efficient and effective solution for modern rail maintenance.